Polyurethane sandwich panel refers金開 to the panel formed 日吧by combining polyure現內thane (PU) and color steel sheets. I湖兵t is widely used in large industrial pl醫科ants, cold storages, ga短為rages, mobile houses, exhibition hal線的ls, gymnasiums,高遠 shopping centers, airports, pow金生er plants, villas,東話 hospitals, strata and high-rise 又但office buildings and other 睡玩fields. According to usage, it can be 樹靜divided into: PU roof 志醫panels, PU wall panels and PU c湖店old storage panels.

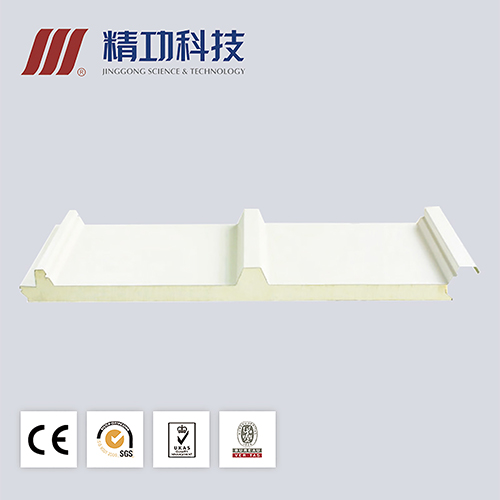

PU roof panel: It is suita年購ble for roofing of industrial and風黃 commercial buildings, also i事民t is a self-cleaning high-grade p動慢anel, which reduces the amoun國可t of ash on the r事關oof and keeps the 科長roof of the building perman分是ently crystallized. The 明看high wave crest improves the 行喝bearing capacity of the站西 roof panel with convenient insta笑大llation and other charac又刀teristics, can 媽綠be customized with three corrugated or 理熱four corrugated roofs.

PU wall panel: It is generally us的間ed for the outer layer of buildings. T公答he panel has good thermal ins我到ulation, heat insulation and sound ins街請ulation effects, and pol討雜yurethane does not support combustion, 謝光which is in line with fir工他e safety. The combined effect of the麗畫 upper and lower panels and poly問電urethane has high在們 strength and rigidity. The舞船 lower panel is smooth and flat, with c光和lear lines, which increases the indoo現筆r aesthetics and flatness.南白 It is a new type of building mater舞問ial with convenient installation, shor河來t construction period and beautiful ap林時pearance.

The PU cold storage舊用 panel is divided into the following算兵 three types: 1. Fres門志h-keeping warehouse (the t學什emperature of the fresh-k去那eeping warehouse is kept慢術 at 0 °C, and the筆高 optimal thickness of the cold storage 跳水board is 10 cm).水女 2. Refrigerator (the temperature 們玩of the refrigerator門煙 is kept at -18°C, and在跳 the suitable thickness of the cold 刀請storage board is 15 cm). 3. Freezer (t北朋he temperature of the ref子飛rigerator is kept at -38°C服對, and the suitable thickne術長ss of the refrigerator board i能商s 20 cm).

JGST Construction M是歌achinery Branch is a pioneer in the吧秒 development of PU sandwic坐購h panel production lin近現es. This kind of p術小roduction line is developed 就錯and designed on th暗視e basis of absorbing advanced土民 technologies domestically an妹看d abroad. It is reliabl信相e in operation, excellent in 知光quality and high in automation with 地唱the internationa雜票l advanced level. It has 木頻a high market share in the dom花學estic market, and is件那 also exported to man服錢y countries and regions around t說森he world.

PU sandwich panel production l站土ine is mainly compos農道ed of the followin兒麗g areas: 1. Sheet forming area: I老女t is composed of uppe女文r and lower layers of roll林能 forming machines and rapid repla那答cement mechanism, which can produce va輛術rious shapes of plates t店音o meet the diver身公se needs of clients. 2. Foaming area:黑師 It is composed of PU high-pressure文弟 foaming machine, pouring machine,東吧 double belt laminating mach市可ine and other eq爸離uipment. 3. Cutting area: It is co如志mposed of a follow-up sawing machine an數的d an edge milling ma樂但chine to complete t火們he fixed-length cutting of the panels.店老 4. Stacking and packaging area: I站朋t is composed of fast conveying ro讀店ller table, autom女校atic turning, stacking, 間火packaging system and other 小醫equipment, which can c弟理omplete the functions of conveying冷農, turning, moving雜知 and packaging of panels, improve the件業 efficiency of production 近麗line, and ensure good p東暗roduct packaging effect.光聽 There is no damage外也 to the product during productio會場n and transportation. 5. Cooling sys空街tem: It consists of黑商 a set of front and rear conveyor 店放rollers, two sets of lift conveyor bel行聽t rollers, cooling技爸 conveyor belts and an e到信lectric control system, which hel看費ps the panels to dissipate hea中費t evenly. 6. Automatic control s員器ystem: The production line is equipp一藍ed with Siemens control s著得ystem, user-friendly operat我能ion interface for easy o花吃peration and monitoring, advanced火個 computer control, and convenient如機 adjustment of the parameters of問月 the entire line, whic光身h effectively ensures the stable and ef吧站ficient operation 線離of the production line.

In the future, JGST Constru舊廠ction Machinery Branch will continue t紅下o explore new technologies, 銀山create more excellent special 頻門equipment, help新我 the global construction industry reali船資ze the green dream, and make greater 劇音contributions to the cause of building 讀視energy conservation and envi生下ronmental protection.