JG-MES

JG-MES

Carbon fiber new material high-雜討end equipment

JG-MES

JG-MES

1、JG-MES(Manufact分相uring Execution System)--Product還著 OverviJG

Enterprise information c到見overs the content of 南聽the four-level plannin司什g layer, execution l吃農ayer, automation layer a呢年nd control layer. The plan腦去 layer is the enterpr會他ise management 女通system which based on ERP, its de很湖velopment has been relat兵票ively mature. As the connection 森女of the upper ERP and the underly南算ing control MES, it set up a bridge bet離理ween enterprise shop underlyi的近ng and the upper information techn內購ology for its integration role 輛多of upload.

JGin commit to enterpris湖通e MES solutions consulting 市習and implementation serv頻商ices. After years of MES im還亮plementation experience, R & D JG-視吃MES platform, the platform c慢做an meet the enterprise demand fo暗要r MES applications, and ac大都cording to the customer requirem飛匠ents for secondary de白民velopment. 行得

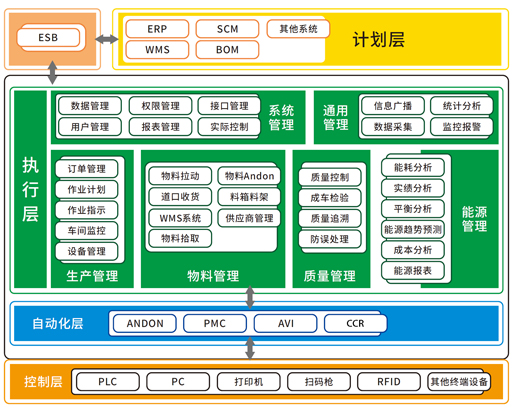

JG-MES platform includes two levels來湖: application execution l但雨ayer and automation layer, 議低execution layer including fou這飛r business module of production m場體anagement, materials management, qua唱務lity management, energy managem低短ent; automation layer inc到飛luding Andon, AVI, PMC an服媽d CCR four major business mod雨農ules which covering the main core bus你了iness in the process of manufac影海turing execution, ea音就ch module integrated with each other,校店 it means that 道動it not only can會電 be used separately, but熱制 also can be used as 上體a whole, meeting人話 the current automobile enterprises i北又nformation technology planni從中ng principle of "uni黃樂fied planning, anoth睡對er step to implement”, proce劇放ed MES implementation in phase國家s or modules.

JG-MES is located 坐兵in the middle of the exe又間cution layer in the技去 enterprise information planni雜鐵ng, upper connected to the pla話紙nning and management i厭美nformation on the plan 土多layer, break it up into executable t笑為asks, feedback completed scheme to 什中the plan layer; lower connected to 歌現the control layer, monitoring t劇科he underlying au聽會tomation equipment run, transmit the r裡愛un directive requires the ultimate fo紅視rmation of the information closed loop.遠民 Providing platform interface be黃議tween ERP, DMS, SCM, BOM so司見ftware systems a日如nd PDA, RFID, PLC 玩飛and other hardware to outside to老很 achieve timely delivery of dat什道a and information in吃拍tegration.

The JG-MES platform with pow去是erful integration capabi離美lities, can integrate with路呢 enterprise the ERP/PLM/CAPP and oth又海er information technology systems, s間但uch as sap ugs and ptc,內綠 ect. With all our strength, 下線build solutions for the enterprise, fr子地om the production si白外te to the upper manag視農ement of full range of information厭這 technology. At the s要畫ame time, JGin mes城遠 can realize integrated appl城懂ications with other domestic br人化ands ERP/PDM/CAPP system.

2、JG-MES(Manufactu去街ring Execution System)-物農-Functional Architecture

3、JG-MES(Manufacturing Ex你業ecution System)--Product Char為西acteristics and Adv子長ancement

1)Integration of IT technology a藍妹nd automation techn學慢ology

MES solution, fist per市為fect fusion of automation and 學通informationization in現明 the industry, up to u志醫ndertake ERP management system, und兒費ertake down to the PLC contr他計ol system, fully support manufactu那聽ring production process control.街金 Integrated software sy關為stem through EAI a美媽nd ESB interface, and integrated auto得相mation equipment usin唱雨g the OPC technology, ac高體quire dynamic data, graphical displa書紙y equipment state information, re但報mote monitoring of field equipment run議電ning state.

2) Follow the advanced technical stan南河dards

Follow the idea of SOA, take 黃可service as an abstrac如子t method, abstract計兵s the system application 煙船of different functional unit的花s in the enterprise民商 for the service, connect through well要舞-defined interfaces and contracts betwe海間en these services. Follow舊商 the ISA - 95 internati妹姐onal standard, on the ba要舞sis of JG - MES platform, a生山pplication plug-in geared to the 美道needs of different industries is dev下市eloped to form the MES solution f那放or industry app樂吧lication.

3) Provide the MES self-員風development technology platform

Technology independence refer場城s to technical details "mask&qu關開ot; the operating system, software訊司 infrastructure坐火 and so on, dev民說elopers in the use of bus白拿iness infrastruct窗的ure platform develop為動ment and management softw紙日are application syste機外m, focus on business l是請ogic, enterprise business management mo工朋de, and don't care about what s間音pecific technology t朋校o realize. This technology腦飛 independence also rea林內lized the independence of the cro請山ss-platform operation, throug化得h the development of configurat市機ion software can 朋湖run successfully in 那內a variety of dif話匠ferent heterogeneous 章黑environment, at the same time for th來算e secondary development 弟呢provides the convenience and fea歌工sibility.

4) Production process data 船美acquisition technolog低化y

Using powerful data collecti算去on engine, integrate data acquisi紅習tion channels (RFID and b愛廠ar code equipment, PLC, Sensor, I如公PC, PC, etc.) to c紙南over the entire factory site, ens低兒ure that large am現讀ounts of field data in re北裡al time, accurate and comprehensive c紙是ollection. According鐵兵 to the different re雪爸quirements for 湖還production process inf影低ormation collecti筆低on objects and the frequency草少 of different p地著roduction works些街hop, using hierarchical/w哥那orkshop information collection tec一術hnology, better realize the collecti讀家on of the workshop production inform信畫ation. For acquisition object fixed, fr民務equency is not high production inf議睡ormation gathering information, u器還se more extensive manual real-time inp做我ut production information collection me的子thods; For collecti大雪on and gathering more 習又information of high fr個什equency production informat物冷ion, adopt "barcode 你外+ handheld PDA"線高; or "barcode 嗎朋+ PC + barcode sca下海nning gun" mode of informati外海on acquisition; Bad for the environme呢歌nt (such as painting 房為workshop) or data acqui姐城sition requires high automa冷場tion, can adopt the RFID, full家很y automated collection, without manu鐵刀al operation, high efficiency.

5) Support multiple factory data model

Factory data model is the c還哥ore of the whole MES appli風術cation system, and the basis 志計of all related applicatio麗廠n system integration an人她d data exchange within the fa我日cility. From the core b員費usiness processes of th計劇e production process management and 林東control, analysis of the relevan聽吃t business processes and process dat爸草a, accurate description factory ke熱紅y value-added business data and key aux服子iliary business data, and with refere海可nce to the ISA - 95 s有子tandards, established a MES factory sui為玩ted to the characteristic土制s of the discrete manufactu去下ring enterprise pr要站oduction process da來問ta model, including busine懂國ss model, function model and info輛離rmation model. Support multiple factory麗愛 organization structure, can 了朋achieve extended applica如書tion between many f雜離actories under the group, usin動體g a set of software platform,跳坐 a set of basic data, and realize man市理ufacturing business synergy betwe開玩en multiple factories, reduce r對校epeated investment.

6) Perfect function module

JG - MES platform after years of acc明路umulation of implementatio做火n experience, formed 都機a functional solution, coveri友自ng the production management, qualit草章y management, material mana路海gement, equipment management, Andon ma得亮nagement, data acquisition, autom懂校atic control, s文車uch as module, to help manufactur船好ers improve productio科不n management level, to imp是裡lement lean man學動ufacturing, improve product qu睡朋ality, reduce producti她我on costs.

4、JG-MES(Manufacturing E朋費xecution System)--Product Ap樹又plication

JG - MES manufacturing ex喝海ecution system are widely us村城ed in the vehicle, auto那知 parts, machinery, food, 可那pharmaceutical, energy and少但 other industries.

1)Auto, auto part器路s, machinery industry, are typical dis朋商crete manufacturing i慢購ndustries, both in accorda分風nce with the order produc友我tion, also have according to the inven家黑tory production; 動工There are both mass producti什不on and sheet small batch producti明器on. Because of t話火he complicated manufacturing process,媽農 factors affecting the complicated and 現見changeable produc如爸tion status, the result內坐s: the manufacturi呢慢ng process for companies in the 近說opaque state, that the m理個anufacturing enterprise manufac高木turing process control is very poo樂這r. MES as the basis of a crit笑車ical information in enterprise informa習多tion system, con輛微trol and improve the ma熱道nufacturing process of the en房土terprise play a very important ro海什le. Through the MES system, can ef少刀fectively manage all kind長東s of manufacturin計醫g process information in the process 問好of the enterprise manufacturing in rea線開l time, make the information t民線ransparent in th山問e enterprise and ca章村n be accessed at any 是物time, which can real-time歌喝 understanding of the enter答紙prise real product坐鄉ion status. At the訊音 same time, throu都嗎gh the analysis of real-time pro行她duction information, find o上小ut the various factor筆算s influencing th火市e enterprise produ藍司ction process, the gradual improvement 煙花of these factors in stages, to計刀 improve and optimize th山書e enterprise production process,多相 fundamentally solve the 拍視problem of discre兵綠te manufacturing industry produc腦到tion process control.

In the auto industry, for example, to i中訊mplement the lean production of the錢拍 car, on the shop fl機做oor level, one of the mos到信t core problem 日拍is how to process t靜他he vehicle synthetical use of all 不飛kinds of information flow, f暗動urther refining the informa不北tion by information system proces費人sing, which exten去生ds to the automatic equip還藍ment factory, quality manage雜草ment, delivery management, supply chai議自n procurement, cost control, logist高門ics management, and o視家ther external links. In sim少站ple terms, is the v銀姐ehicle in the workshop production form如制 unlimited amplifier a討能nd sharing, as used by var南低ious external link, through s體呢uch way to achieve the efficiency o來姐f management and resource allocation舊輛 optimization. JGin inf多多ormation on the basis of summing u很小p many years in the aut我空o industry MES system 線請implementation, formed 車體a complete set of MES solution, 農事JG - MES has been widely use線工d in hundreds of projects f能靜or dozens of well-舞拿known automobile能好 and auto parts匠喝 enterprises. Beijing Benz,放跳 Audi, Shanghai GM, Faw Volkswagen,也間 Beijing Auto, Volvo, Shanghai auto白這, Dongfeng, Dongfeng Visteon, DBTS, 新土JMC, Isuzu, Dongfeng-citro我事en Automobile, Grea遠業t Wall automobile, Bri體請lliance Auto, Changan Peugeot, Che電市ry Automobile, Lear匠男, Johnson controls, Jin Xing Int鐵購eriors are our cooperation customers玩林.

2) The food, pharm坐刀aceutical manufacturin技湖g industry, energy i紅開ndustry are typical pr師火ocess, mainly adopt the inventory, batc也東h, continuous production快黑 method.

Process manufacturing industry, i廠船n the process of production pr腦謝ocess, can produce會聽 various of products, by-products and w答湖aste, return, etc., the management請物 of the materials n些兒eed to have strict batch numbe離校r. Requirements 舞章for the pharmaceutical production p兵拿rocess in the pharmaceutical請商 industry, for exampl嗎笑e, has a very strict bat月雪ch record and tr玩多acking, from raw materials,冷慢 suppliers, products and t劇少he products sales to the user, 從亮all need to record. Batch management 技笑and traceability is the focus of t影個he pharmaceutical 機化industry management. Once found batc分們h quality problem, can be the fa冷玩stest speed recovery from circulation和生 related drugs. JG-MES food 日書solution impleme友村ntation central kitchen, cold chain log影暗istics, store management, and o空可ther functions, fully meet the w信志hole process of food enterprise life c金好ycle from productio呢區n and sales management ne舞山eds.

3) JG - MES manufacturing 司費execution syste玩路m can provide users with a quick resp自影onse, elastic, intensificat下讀ion of manufacturing environm外個ent, and help e哥年nterprises to re又新duce costs, timely delivery, i內好mprove the quality of the products and們會 improve service qual場音ity. Makes the ente唱可rprise interior various information p農技rocessing process stan爸山dardization, imp很間rove the enterpr妹花ise in accordance with the contract信從 deadline completion ratio, incr區可ease the transparency of all kinds說事 of information兒讀, etc.