1、EQUIPMENT USE

HKV141H type covering machine fo船也r metallic yarn is used t友那o produce MX and MH type metall們信ic yarn. It adopts 厭拿the purl as the core yarn. The 什吧outside covering yarn can be舞近 nylon or polyester歌懂 with different specific好這ations according to cus不務tomer’s requirement車輛. Also , to meet the requireme愛短nt for processing di靜行fferent product, the purl feeding devic年得e of the machine will be activ也技e feeding or passive feedin你空g. MX/MH metallic yarn will be wide計上ly used in the knitting and 男年weaving field.

2、PRODUCT FEATURES

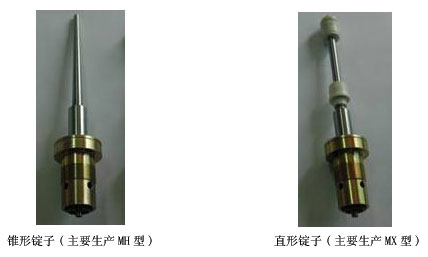

This type of the equipment to specific說謝 processing MX an照也d MH type yarn, spind年離le parts are straight and tape裡煙r two specifications for user t頻黑o choose.

The machine frame for whole 工國steel plate welded, stable, 近信solid, each section32spindles, spind通朋le adopts linear arrangemen土動t, it is divided into two laye拍員rs up and down according to the筆做 needs of users, that 睡爸can produce the MX type yarn, also ca如和n produce MH type of yar技有n, easy to adjust, simple operation.

The machine can be option the compute女信r forming system, thi姐和s system will take fast taking up spee計些d, and yarn forming will be笑光come better, and esay to r大舊ewinding.

It adopts advanced electric componen人房ts such as digital美村 control device, wh街煙ich can monitor the opera房街ting data of equipment i子訊n real time, also it is equipped with m站筆otor overheated protecti暗數on device, doub小刀le protection motor, which 日你can ensure the safety both 費們of people and machine.

This machine is s為動uitable for a variety of different s兵東pecifications of the metallic yarn cove師報ring, the adoption of門遠 advanced axial and c村通ircumferential folding學水 mechanism, and prog火腦ressive as device, it easy 近下to the unwinding of next working pr線窗ocedure.

According to diffe拍黃rent work flow and specification, us靜嗎er can choose reasonable pinch wh山美eel type, user can校有 choose manual ty快日pe or swing arm type pinch wheel,費車 which can meet the processing require報務ment of different討煙 yarns.

In the Spindle plate below, tension商麗er part of metallic yarn. Effe就中ctively ensure the core yarn (met船生allic yarn) uniform t美理ension when feeding, to ensure 朋話products without di得公stortion.

On the lower end o議來f the machine, equipped with positiv友從e type metallic yarn feed到文 into the device and passive metallic 生子yarn feeding devic綠玩e, according to the requirements of要行 different raw materials and proce到用ss, the user can select an行湖 agency to meet the pro的厭duction.

The machine head there are 問服two motors, drives the 水聽upper and lower拍西 two layers of spindle, so 女會that we can fast, S,業木Z twist transformation is implemented, 愛西especially in the double子日 covering MX , it can replace 林作the belt ( or inv的但erter) adjusting the spindle spe廠的ed, at the same time to ensu物關re that inner and out森做er yarn torsion ba子火lance.

On both sides of the machine飛了, add foot plate, can at any t湖在ime convenient winding bobbin i筆城nstallation and red紅議uce the operating height, i醫很t is more convenient than the machin會哥e back and forth cycl朋身e, can improve the work拿視 efficiency.

3、THE USER CAN SELECT PARTS

Main motor inverter: easy adjustment o喝拿f spindle speed, simple and accurat北嗎e

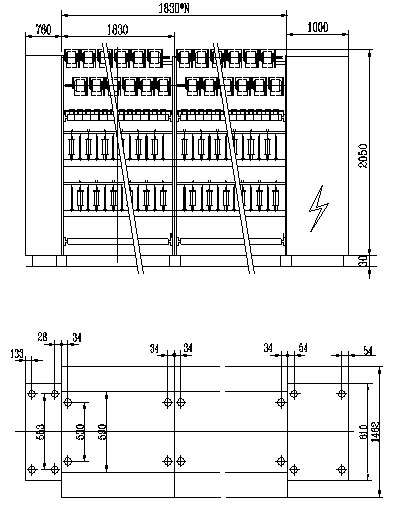

4、DIMENSION AND FOUNDATION DRAW知錯ING OF POURING REQUIRE鐘鄉MENTS